Ecolite is an excellent alternative to concrete blocks and clay bricks and matches or outperforms them on numerous parameters. Ecolite offers AAC blocks and lintels made from environmentally friendly raw materials. Portland cement is mixed with quartz (silica/PFA), water, and an aeration agent and poured into a mould. This mixed and moulded sustainable concrete is autoclaved under heat and pressure, giving Ecolite unique properties.

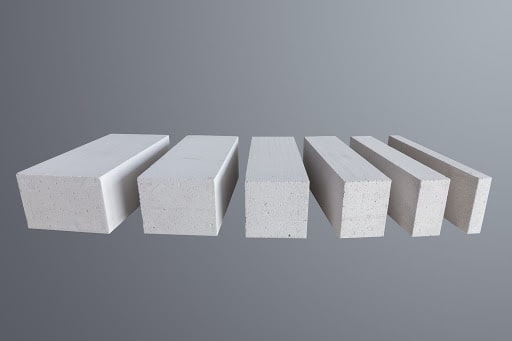

Ecolite AAC Blocks

Ecolite AAC blocks are a Grade 1, non-organic, non-toxic, lightweight and airtight material best for

walling with high strength and thermal insulation properties for use in load-bearing and

non-load-bearing structures for interior and exterior applications.

The significant benefit of installing Ecolite AAC Blocks is that the brand offers a complete walling

solution with sustainable jointing mortar and plaster. The brand provides consistency in quality,

best-in-class service, minimal wastage in transit and end-to-end technical assistance. The blocks

come in a range that suits the customer's exact applications. The blocks come in a range of Regular,

XL and Mute.